-

Spectrum 16/48 Heatsink Info

There are two main types of heatsinks used for the rubber key Spectrum (and Spectrum Plus). A smaller, angled heatsink was used on Issue One and Issue Two boards – this is fitted to the 7805 voltage regulator in the bottom right corner of the PCB. All the later boards use a long, straight heatsink – attached top right.

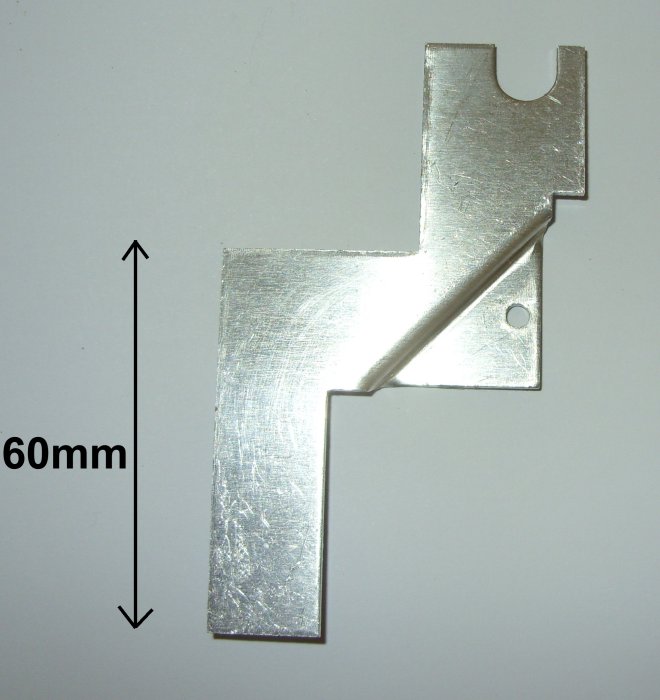

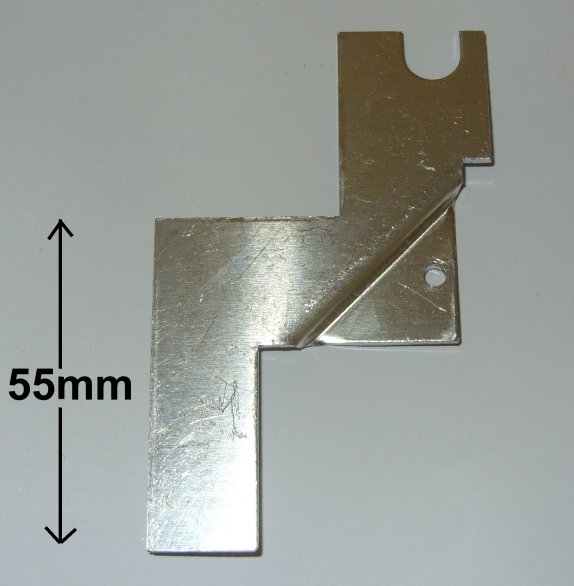

When an Issue One/Two PCB is used in a Spectrum Plus case, the heatsink has to be cut down to fit – approx 5mm needs to be removed from the the bottom edge – see photos below.

The later, straight heatsinks usually have a foam pad (or pads) stuck to the top surface on the right side (vertically in line with the keyboard connector) – this is to prevent the fragile keyboard membrane tail touching the heatsink (which could lead to heat damage and/or undesirable capacitance effects). Due to the different positions of the membrane tails – this is more of an issue in the Spectrum+. The foam pads often break up with age (however, Samsung used a better quality foam pad on their “4S” boards and these still seem fine, much like their membranes!)

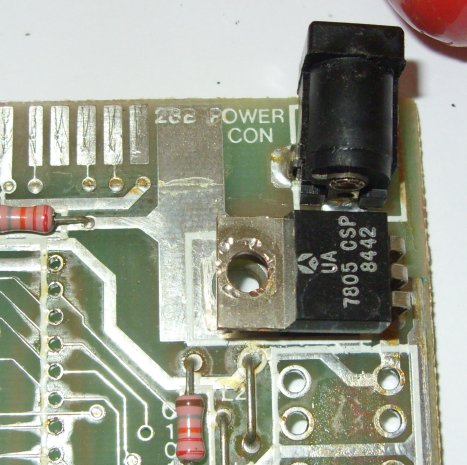

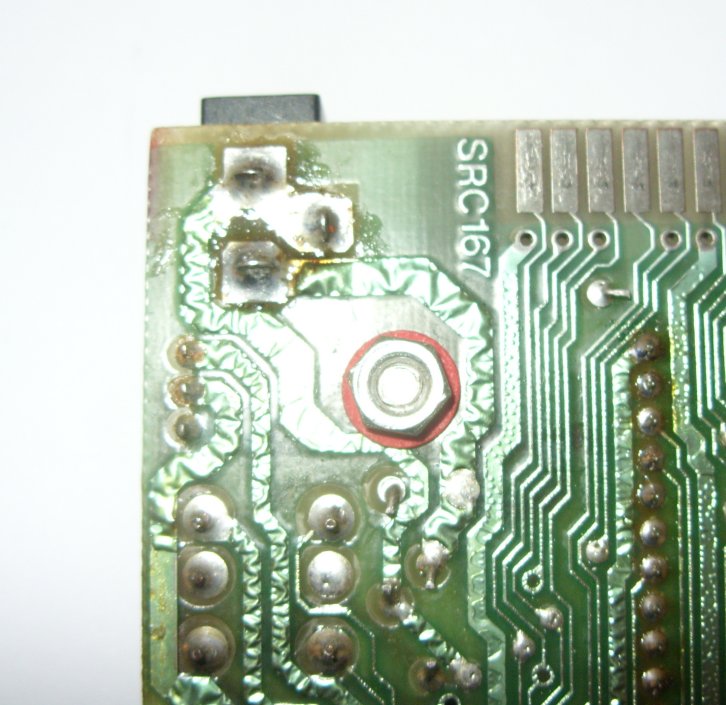

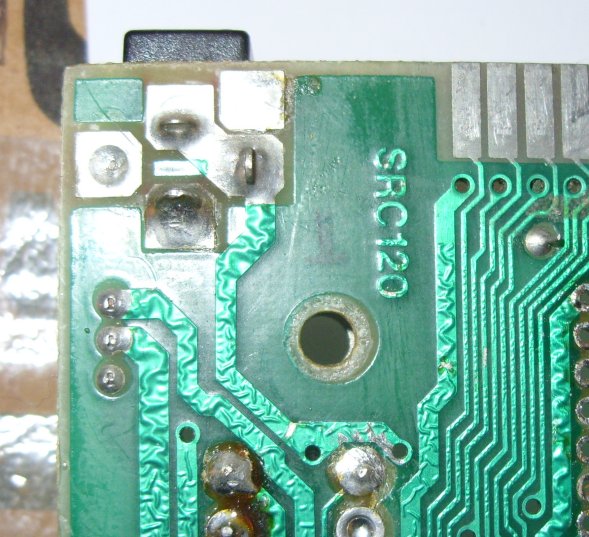

Both heatsink types are attached with a 4BA bolt, this is usually a slotted 5/16th inch “cheese-head” type bolt with appropriate spring (or star) washer and “half-nut”. Sometimes a red fibre washer is used for insulation on the bottom (see details below). Issue 4S boards use a brass domed Philips bolt with standard height nut. More often than not, no heatsink compound was used between the 7805 regulator tab and the heatsink (it certainly can’t hurt to add some if available). On occasion, the end of the bolt (or nut) may hit the surface of the lower case and create tension in the PCB when assembled – this can happen when the spring washer is missing on the top side or a longer bolt is used. If this is a problem (and a shorter bolt / packing washers for the top side aren’t an option) you can try putting the head of the bolt on the underside of the board.

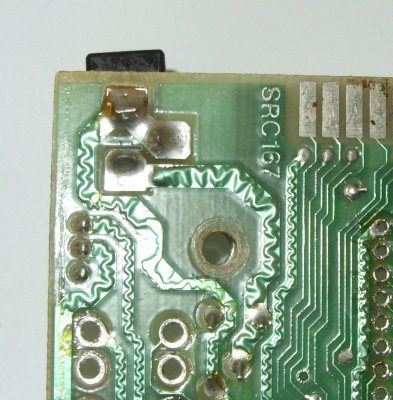

Some boards have PCB tracks very near to the heatsink bolt hole. EG: The Issue 6A PCB requires the use an insulating washer on the bottom side to prevent a short circuit between the nut/bolt (connected to the 7805 regulator tab – ie: ground) and the DC supply when the nut is tightened. Also, some boards have components on the top side very near the heatsink attachment – a slight twist of the heatsink could short them out. To help avoid this possibility, a small piece of masking tape was attached to bottom edge of the heatsink mounting tab (photos below).

Without a heatsink, the Spectrum’s 7805 regulator will overheat in about one minute. However, it is possible to remove the heatsink entirely if the old inefficient 7805 is replaced with a modern “switch mode” type regulator (which does not waste energy as heat). The Murata / OKI brand 7805 replacement is recommended as it is rated up to 1.5 Amps (the peak current of the original 7805) but the 1-Amp rated Traco type is known to work fine too.

Replacement heatsink hardware and switch-mode regulators are available from the retroleum store.

Full size Issue 1/2 heatsink

Cut down Issue 1/2 heatsink

Issue 3-6A heatsink

Partial insulation to avoid..

..nearby component leads.

Nearby traces on issue 6A

Fibre washer fitted to 6A

Traces clear, no washer req’dInstalling additional heatsinks:

Adding heatsinks to Spectrum chips can be tricky due to the lack of room inside the case. Ideally, the ULA requires a heatsink but this can only be achieved in the rubber key Spectrum if the ULA socket is removed and the chip is soldered directly to the PCB – a 5mm high heatsink can then be attached (beware that soldering a 35+ year old IC is not without risk). There is more room in the Spectrum+ case and a 5mm heatsink can often be added to a socketed ULA without fouling anything. However, there are screw heads on the underside of the keyboard plate that may be in the way especially with keyboards that have a thick plastic backing plate – test fitting is advised before anything is permanently stuck down.